Successful completion of extensive heavy-duty work at the Allmendingen cement plant

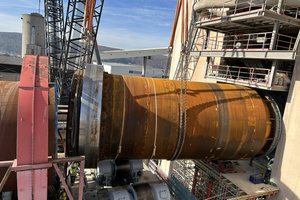

The cement plant in Allmendingen was in the middle of an extensive major construction site as part of the annual winter shutdown. This year was a particularly intensive and challenging inspection period. Individual sections of the 96 m long rotary kiln, including roller bearings, have reached the end of their service life after a good 50 years of operation and have been extensively replaced. Rotary kiln plant 4, the centerpiece of the Allmendingen cement plant, has been shut down for this work since the end of November.

Installation of heavy components successfully completed

After 10 weeks of downtime, during which the old plant was dismantled and the kiln foundation replaced, the last three large components of the kiln plant were lifted into place and positioned on 29 and 30 January 2024. The heavy load of the individual parts posed a particular challenge. The heaviest part, the pre-assembled kiln shot, weighed 247 t. The pressure roller weighing around 35 t and the furnace shot intermediate piece weighing around 34 t were also installed.

“A 600 t crawler crane was used for the heavy lifts, which was mounted on a bed of gravel and wooden planks laid especially for this purpose. It took 3 days just to set up the crawler crane. In comparison, the large lift was successfully completed within 3 hours,” explains Thomas Braig, Head of the Technical Office at Schwenk’s Allmendingen site.